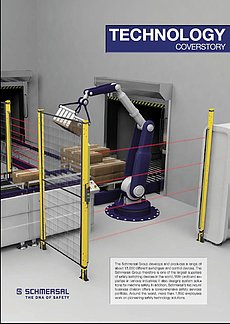

Technical articles

We offer a selection of technical articles dealing with the safety of machines and plants - both in general and on particular aspects of product families for machine safety. Some of the contributions are from Schmersal employees, others are written by independent specialists, e.g. from industrial assessment organisations. The applicable PDF file can be stored on your computer by means of the download function.