26.04.2019

Protects people – increases plant productivity

Automotive Engineering Show Chennai: Schmersal exhibits safety solutions for industrial robots and Industry 4.0

Wuppertal / Chennai, 26 April 2019. Robots are the backbone of Industry 4.0 and are gaining ground all over the world. But compliance with strict safety requirements is a basic prerequisite for the operation of robot systems in production. At the Automotive Engineering Show 2019 in Chennai the Schmersal Group is showcasing an extensive range of coordinated safety components and safety systems for industrial robots. “These products allow a wide range of robot workstations to be reliably and efficiently made safe, to protect people and at the same time, increase plant productivity”, says Mr. Sagar Bhosale, Managing Director, Schmersal India Pvt. Ltd. “In India, we have an own R&D team to develop solutions that are adapted to the specific requirements of the Indian market – and which are produced locally true to the motto ‘Make in India’.”

Safety systems from a single source

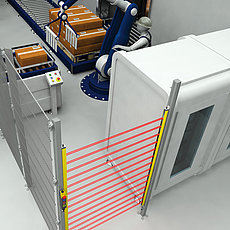

Robotic systems are often secured with separating protective devices, for example with protective fences. Thanks to the cooperation with its sales partner Satech Safety Technology, which produces modular safety components such as protective fences and protective doors, Schmersal can provide complete systems from a single source: Solenoid interlocks from Schmersal ensure that protective doors on robot workstations cannot be opened until the dangerous movements have come to a complete stop. The solenoid interlocks not only protect the operating personnel, but also the production process from unplanned downtime.

AZM201 solenoid interlock / BDF200-SD control panel

With the highly coded AZM201 RFID interlock combined with the BDF200-SD, individually, ready-to-connect safety solutions can be pre-assembled for the safety doors on robot cells. Thanks to the built-in RFID technology, the AZM offers tamper protection as required. In the D-variant of this solenoid interlock, two safety functions are covered by a single piece of safety switchgear. The AZM201-D is therefore particularly ideal for setup mode on robot workstations. Using the built-in SD interface (SD = Serial Diagnostics) in the BDF200-SD, the non-safe diagnostic signals from the command and alarm devices can also be transferred via an SD gateway to the controller. The status data and diagnostic messages can be used for preventative maintenance, thus contributing to improving machine availability.

Opto-electronic and tactile safety equipmentSchmersal has developed various ranges of safety light curtains and light grids which fulfil different requirements and guarantee economic access protection for robot workstations while taking up very little space. A safety field made up of infrared beams is sent by the transmitter and evaluated by the receiver. If an object or a person breaks the safety field, a stop signal is immediately triggered in order to stop the machine.

The safety switching mats from Schmersal allow monitoring of whole areas, not just access points. They guarantee step-back protection, i.e. as long as an operator is in the hazard area, the machine cannot be started.

Schmersal presents new Industry 4.0-compliant solutionIn addition, the Schmersal Group is presenting a new Industry 4.0-compliant solution at the Automotive Engineering Show 2019: the PROTECT PSC1 safety controller with integrated OPC UA server. The connection from the PSC1 to the industrial machine-to-machine communication protocol allows extensive information from Schmersal products to be included in manufacturer-neutral data exchange. In addition, this solution allows Schmersal products to deliver maintenance information, meaning that – in the sense of predictive maintenance – components can be replaced in good time before they reach end of life or lose the performance level.

Visit Schmersal from 4th to 6th July 2019 at the Automotive Engineering Show Chennai, hall 1, booth B95.